Помилка формату електронної пошти

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Новини

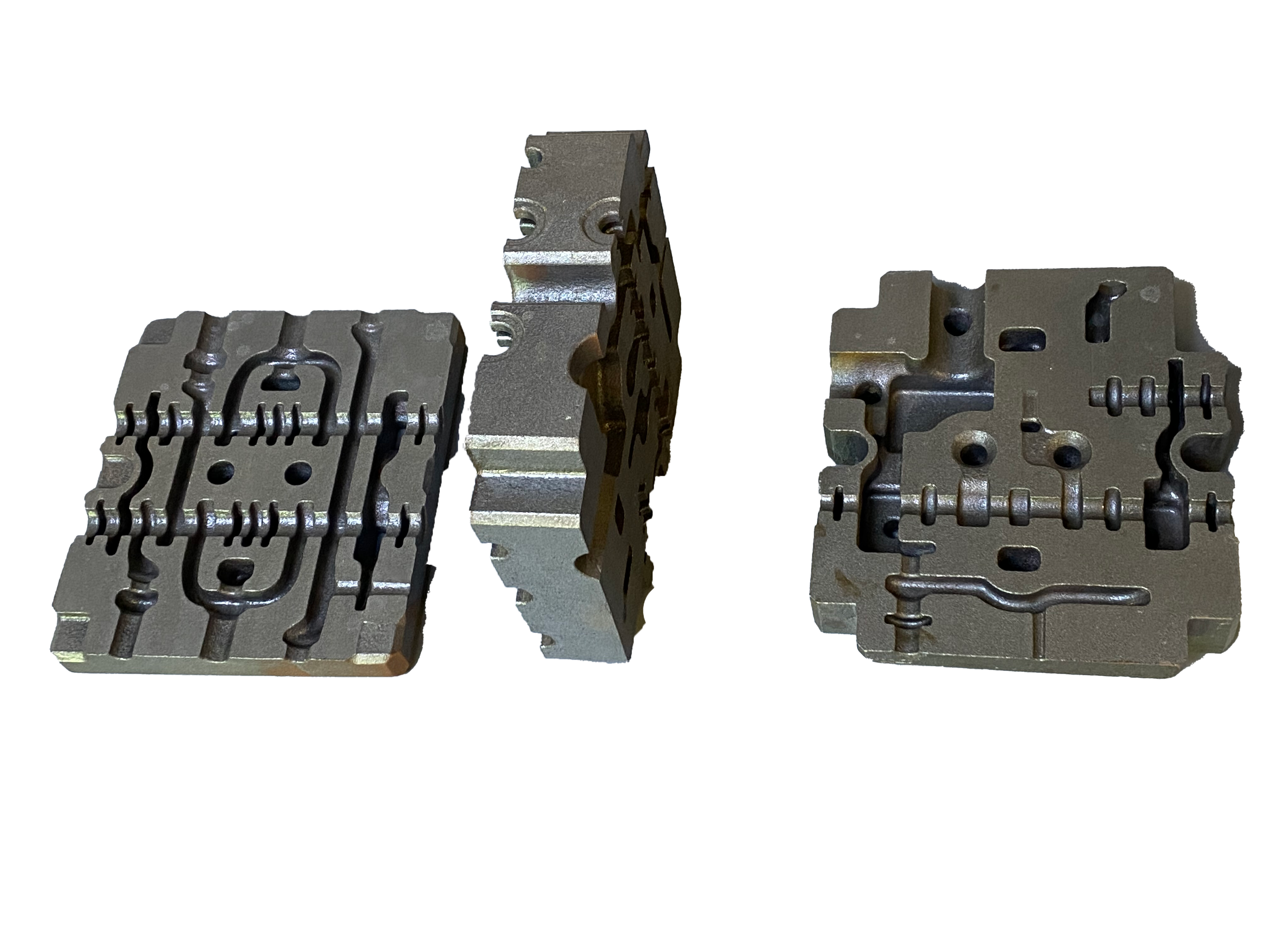

Talking about the Film in Cast Iron(2)

In general, the above results well explain some phenomena observed in cast iron factories. For general grade gray cast iron, the surface of molten iron is very clean at 1420 ℃. When the temperature drops to 1390 ℃, fragmented solid gray films are first observed. These films will grow completely at 1350 ℃ and cover the whole surface. The gray film will last until 1280 ℃, and at this temperature, the film begins to melt and rupture, until it completely turns into a liquid at 1150 ℃.

When gray cast iron is cast in an oxidizing environment, the reduction of temperature during pouring and filling will ensure that the surface facial mask becomes liquid in this critical later stage. If the films are involved in the liquid metal, they will soon spheroid into dense small round drops. The density of these small round drops is much lower than that of molten iron, so they will float quickly. After reaching the surface of the casting, they fuse, and the existing liquid film will absorb them and expand on the surface. The glassy luster on the surface of some gray iron castings may be the skin formed by this solidification method. The harmless distribution of oxide film in this way is also the reason for the good quality assurance of cast iron in green sand casting.

In the casting process of gray cast iron, a small amount of surface turbulence appeared in the inner gate, because it was difficult to reduce the speed below 0.4m/s at this position, so it was concluded that there was almost no risk of internal defects. However, due to the involvement of a large number of liquid facial masks, and these films float on the surface of the liquid metal, a layer of surface slag will accumulate at this position, resulting in a scrap of the casting.

In nodular cast iron, the involvement of a surface facial mask is always a serious problem. Mg added to convert flake graphite into spheroidal graphite significantly changes the nature of the oxide film. When the temperature is higher than 1454 ℃, the liquid surface of the nodular cast iron remains very clean without any film. Below this temperature, a kind of film begins to form and its thickness increases continuously until there are solidified hard shell particles on the surface at 1350 ℃. When the temperature drops to 1290 ℃, a layer of dry scum completely covers the surface. Magnesium vapor is distilled out through scum because the temperature of molten iron is much higher than the boiling point of magnesium. Magnesium vapor is oxidized into powdered magnesium oxide on the upper surface of scum, which is the main reason for the rapid growth of a large number of scum. The slag often gives operators a headache. The formed film accumulates into dry and nonwetting lumps, which are easy to get involved in the molten metal and damage those intact castings. Nodular iron castings are well-known iron castings that are difficult to cast cleanly without scum-type defects.

Make a purchase of cast iron pressure cooker, wirecutter cast iron, lightweight cast iron from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.